ATEX Lighting & Inspections: The Gold Standard for Safety

Thursday 11 February

How ATEX Inspections can help you

By providing ATEX certification you are saying that your equipment meets or exceeds the required ATEX standards required, with overall protection and peace of mind.

Our engineers are highly trained and can provide a full hazardous area ATEX inspection, testing, installation, and maintenance service to clients nationwide throughout the United Kingdom.

ATEX Testing Frequency

To maintain the required workplace protection, all ATEX installations must be inspected on a regular basis. No more than 18 months after the original install, a minimum Visual grade of inspection must be carriedout, with any corrective work arising to be completed. After a further 18 months, a Close grade of inspection is required for complete maintenance.

A new Detailed grade of inspection is required no more than 4 ½ years after the initial installation or previous Detailed inspection of the equipment.

Zone Classifications

Hazardous places are classified in terms of zones. These zones are based on how often and for how long the explosive atmosphere occurs.

The following table explains the zoning schemes that apply:

|

Gases, Vapours & Mists |

Combustible Dust |

Likelihood of Occurrence |

|

Zone 0 |

Zone 20 |

It is present continuously or for long periods or

frequently. |

|

Zone 1 |

Zone 21 |

It is likely to occur occasionally during normal

operation. |

|

Zone 2 |

Zone 22 |

It is not likely to occur in normal operation but if it

does occur, it will be present for a short period of time only. |

Unsure what steps to take?

Remain compliant and save unwanted costs by improving the safety of your workplace with our comprehensive ATEX services. Our trained team have worked on a wide range of installations in areas, including:

- Petrochemical

- Dust

- Bunkering

- LPG

- Forecourts

- Independent high-level alarm systems

- Static earthing and motor installations

We carry out inspections and tests to BS EN 60079-17 (Visual, Close, and Detailed), DSEAR regulations, and APEA (design, construction, modification, maintenance, and decommissioning of filling stations – 4th edition). To find out more on how we can help you, click here.

Watch our latest video to discover what goes on behind the scenes and on-site.

Be sure to stay up to date with the latest news by following us on social media, using the links below:

Latest News

View all

Your Quick Guide To Hazardous Area Lighting

Good lighting is crucial in keeping your facility well-lit and safe, however electrical ignition sources are one of the most common causes of fire and explosion in hazardous areas.

Read more about Your Quick Guide To Hazardous Area Lighting

Share

![]()

![]()

SR Electrical Will Be At CHEMUK 2024 This May!

We are excited to announce that SR Electrical will be at CHEMUK 2024 this Spring! The Chemical UK expo is the UK’s largest annual trade show for the chemical, laboratory and process industry.

Read more about SR Electrical Will Be At CHEMUK 2024 This May!

Share

![]()

![]()

Latest Projects

View all

ATEX Certified Hazardous Area Lighting and Emergency Lighting

Our team helped a business in the food industry improve the lighting in their hazardous areas with the supply and installation of fully compliant, ATEX certified fittings.

Read more about ATEX Certified Hazardous Area Lighting and Emergency Lighting

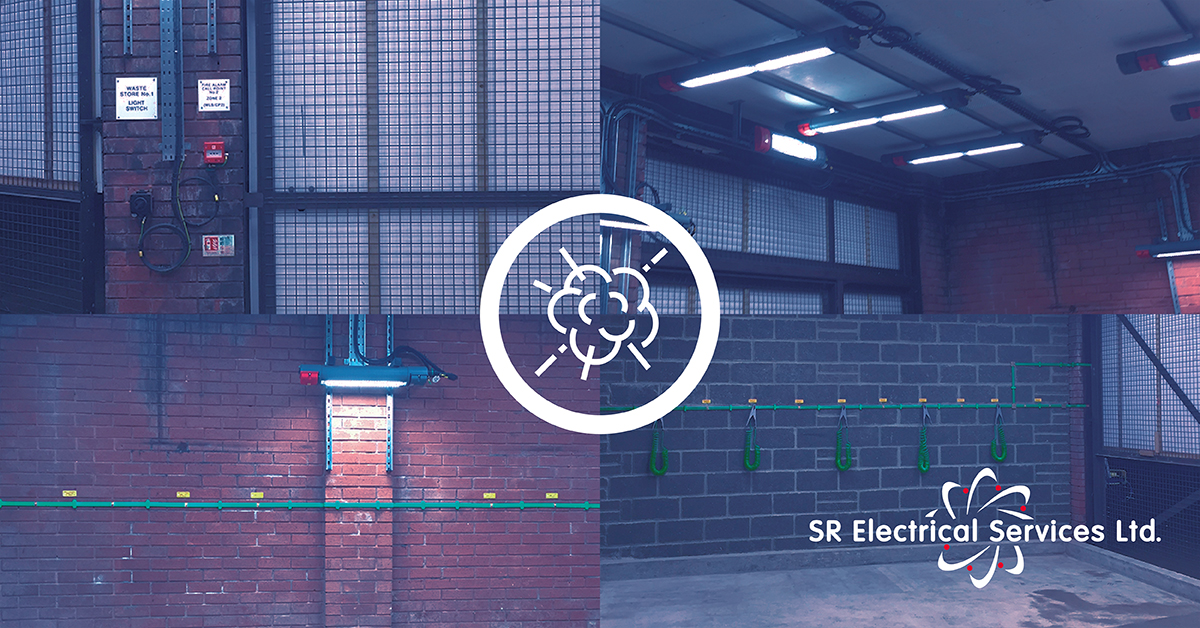

ATEX Lighting & Electrics Installation

Recently, we were called in to help a business in the food manufacturing sector with new hazardous area electrics at their site.