Our team undertook an inspection and testing project at a petrol forecourt.

We were asked to carry out and provide a petrol filling inspection report and a detailed list of defects on various bunkering and dispensing sites through the UK from the Scottish Highlands all the way down to Portsmouth.

The work that we carried out included the following:

- Petrol filling inspection report

- A detailed list of defects and time urgent of defects required to be carried out by ESD testing system recording of testing and numbering of ESD buttons not already done

- Earthing inspection / electrodes testing

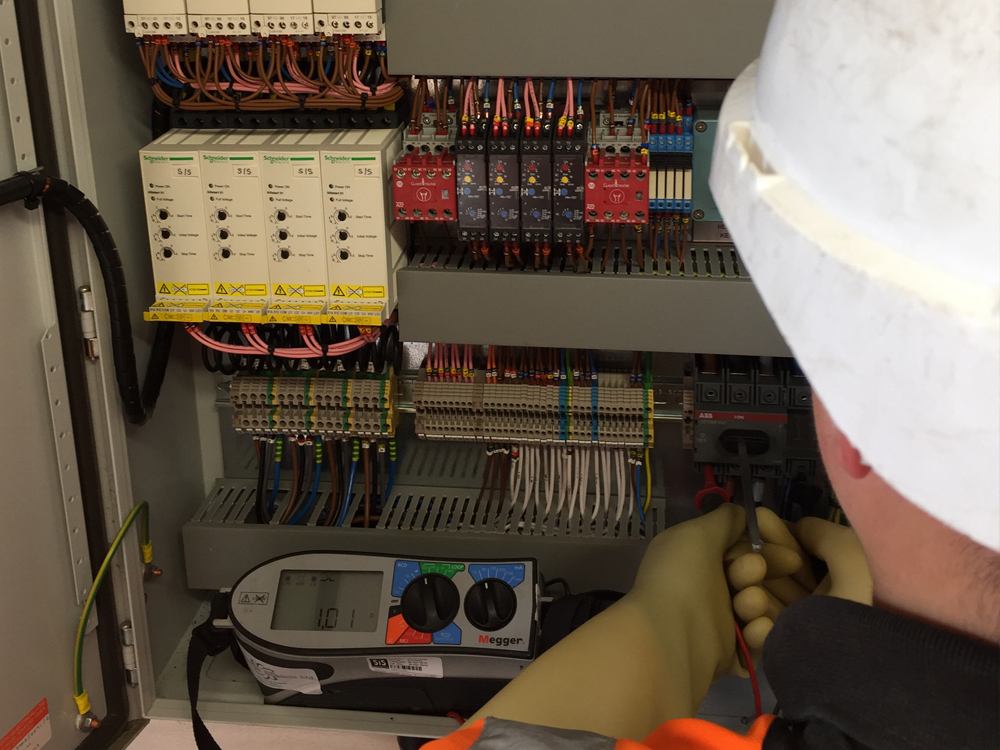

- RCD testing and recording

- Thermal images taken of distribution board and control panels

- Hazardous area equipment sheet and record list

- Testing results of cabling of installation in hazardous areas

After completion of the inspection, we provided a schedule of time and costs to carry out the remedial works of the defects if any found onsite and provide a regular inspection program over 5 years to comply with current standards to allow the sites to keep up to current regulations and maintenance requirements.

Latest News

View all

Your Quick Guide To Hazardous Area Lighting

Good lighting is crucial in keeping your facility well-lit and safe, however electrical ignition sources are one of the most common causes of fire and explosion in hazardous areas.

Read more about Your Quick Guide To Hazardous Area Lighting

Share

![]()

![]()

SR Electrical Will Be At CHEMUK 2024 This May!

We are excited to announce that SR Electrical will be at CHEMUK 2024 this Spring! The Chemical UK expo is the UK’s largest annual trade show for the chemical, laboratory and process industry.

Read more about SR Electrical Will Be At CHEMUK 2024 This May!

Share

![]()

![]()

Latest Projects

View all

ATEX Certified Hazardous Area Lighting and Emergency Lighting

Our team helped a business in the food industry improve the lighting in their hazardous areas with the supply and installation of fully compliant, ATEX certified fittings.

Read more about ATEX Certified Hazardous Area Lighting and Emergency Lighting

ATEX Lighting & Electrics Installation

Recently, we were called in to help a business in the food manufacturing sector with new hazardous area electrics at their site.