Safeguard your operations, protect your staff and ensure compliance with the latest regulations by getting an ATEX inspection tailored to your workplace.

Explosive atmospheres must be carefully regulated, and best practice advises that ATEX installations must be inspected on a regular basis and no more than 18 months after the original install.

A visual grade inspection is the minimum recommendation, however after a further 18 months a close grade inspection should be carried out.

What We Offer:

- Inspection: We will examine your current installations to ensure they meet ATEX requirements. This includes electrical devices, machinery, protective systems and lighting. Sophisticated technology such as thermal imaging cameras are used to guarantee detail.

- Testing: Get your equipment thoroughly tested to assure compliance. We always ensure testing is carried out that works for you and creates minimal disruption to your day-to-day operations.

All of our inspections are carried out to meet the following regulations:

- BS EN 60079-17

- DSEAR Regulations

- ATEX Directives

- APEA

If there are any installation or maintenance points picked up during your inspection, then our CompEx qualified team will be able to give you expert advice and detailed recommendations. We have an extensive history of delivering quality services within hazardous area industries such as oil and gas, chemical, pharmaceutical, manufacturing, food and beverage plus more!

To get your bespoke inspection booked, or to enquire about any of our other ATEX and hazardous area services, then please get in touch with our team today.

Latest News

View all

Hazardous Areas: The Role of Facility Management in Risk Prevention

Facility management professionals play a critical role in ensuring that hazardous areas within the properties they manage are properly maintained and compliant with relevant safety standards.

Read more about Hazardous Areas: The Role of Facility Management in Risk Prevention

Share

![]()

![]()

How To Reduce Downtime in Food and Beverage Production

In the competitive world of food and beverage manufacturing, minimising downtime is essential for maintaining productivity, ensuring product quality and maximising profitability. Unplanned equipment failures can result in significant financial losses.

Read more about How To Reduce Downtime in Food and Beverage Production

Share

![]()

![]()

Latest Projects

View all

Hazardous Area Lighting For A Hydrogen Dispensing Area

We were contacted to supply and install zone 1 hazardous area lighting to our clients’ hydrogen dispensing area.

Read more about Hazardous Area Lighting For A Hydrogen Dispensing Area

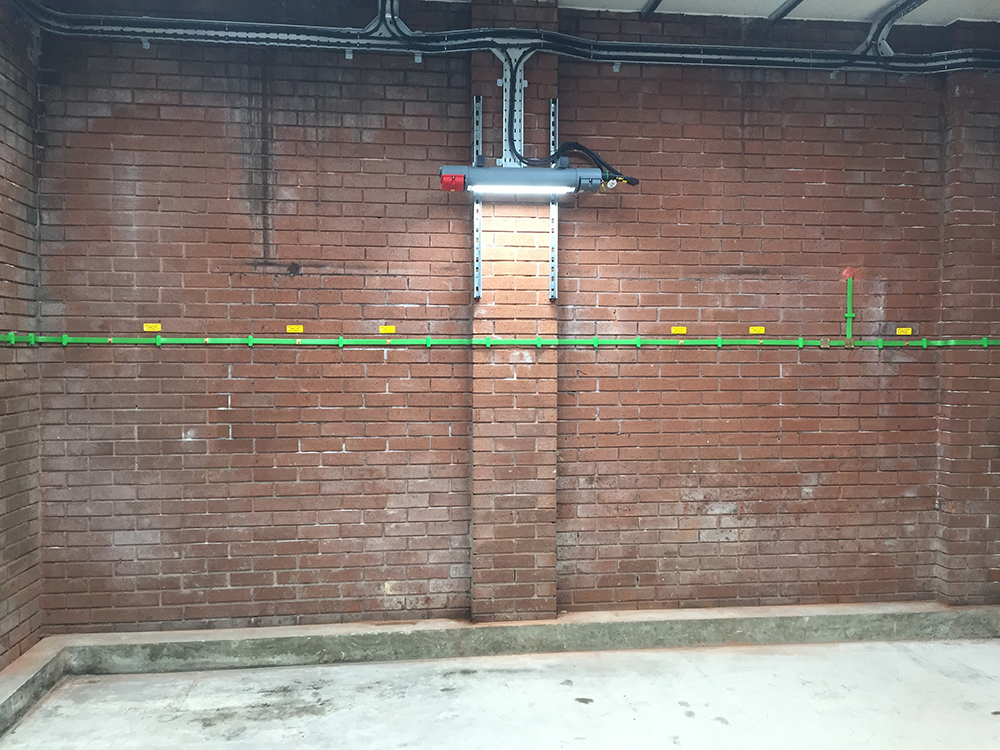

Waste Management Plant Room ATEX Lighting

For a client with a waste management plant room, we supplied and installed zone 1 ATEX certified lighting as well as emergency lighting controls via ATEX certified motion sensor controllers.