Safeguard your operations, protect your staff and ensure compliance with the latest regulations by getting an ATEX inspection tailored to your workplace.

Explosive atmospheres must be carefully regulated, and best practice advises that ATEX installations must be inspected on a regular basis and no more than 18 months after the original install.

A visual grade inspection is the minimum recommendation, however after a further 18 months a close grade inspection should be carried out.

What We Offer:

- Inspection: We will examine your current installations to ensure they meet ATEX requirements. This includes electrical devices, machinery, protective systems and lighting. Sophisticated technology such as thermal imaging cameras are used to guarantee detail.

- Testing: Get your equipment thoroughly tested to assure compliance. We always ensure testing is carried out that works for you and creates minimal disruption to your day-to-day operations.

All of our inspections are carried out to meet the following regulations:

- BS EN 60079-17

- DSEAR Regulations

- ATEX Directives

- APEA

If there are any installation or maintenance points picked up during your inspection, then our CompEx qualified team will be able to give you expert advice and detailed recommendations. We have an extensive history of delivering quality services within hazardous area industries such as oil and gas, chemical, pharmaceutical, manufacturing, food and beverage plus more!

To get your bespoke inspection booked, or to enquire about any of our other ATEX and hazardous area services, then please get in touch with our team today.

Latest News

View all

Your Quick Guide To Hazardous Area Lighting

Good lighting is crucial in keeping your facility well-lit and safe, however electrical ignition sources are one of the most common causes of fire and explosion in hazardous areas.

Read more about Your Quick Guide To Hazardous Area Lighting

Share

![]()

![]()

SR Electrical Will Be At CHEMUK 2024 This May!

We are excited to announce that SR Electrical will be at CHEMUK 2024 this Spring! The Chemical UK expo is the UK’s largest annual trade show for the chemical, laboratory and process industry.

Read more about SR Electrical Will Be At CHEMUK 2024 This May!

Share

![]()

![]()

Latest Projects

View all

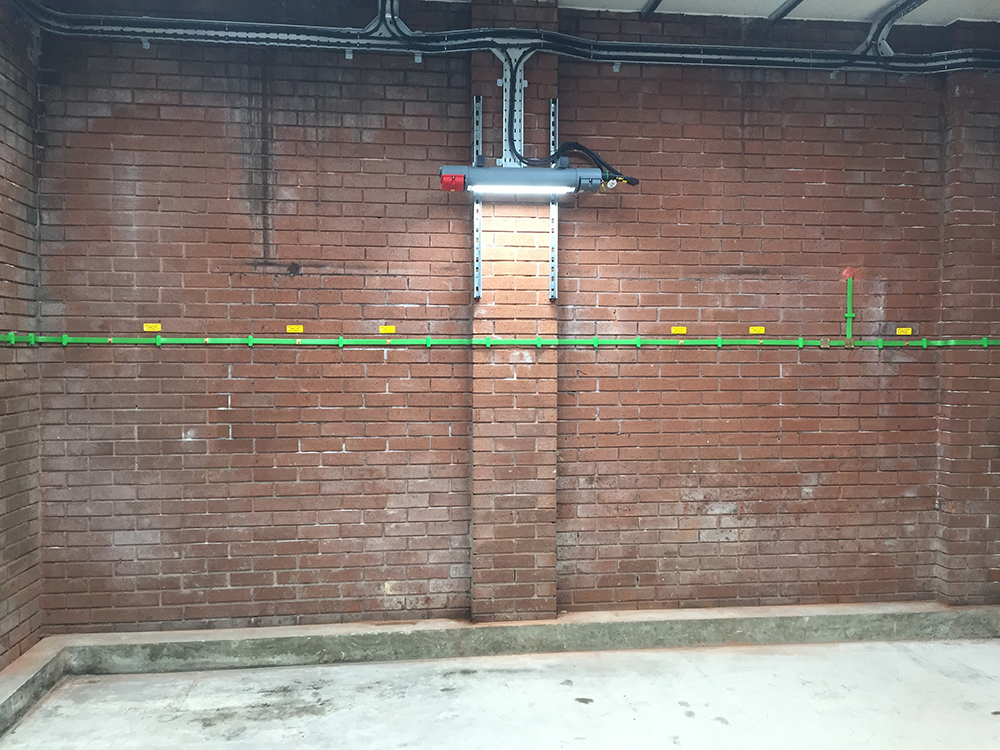

ATEX Certified Hazardous Area Lighting and Emergency Lighting

Our team helped a business in the food industry improve the lighting in their hazardous areas with the supply and installation of fully compliant, ATEX certified fittings.

Read more about ATEX Certified Hazardous Area Lighting and Emergency Lighting

ATEX Lighting & Electrics Installation

Recently, we were called in to help a business in the food manufacturing sector with new hazardous area electrics at their site.