Recently, we were called in to help a business in the food manufacturing sector with new hazardous area electrics at their site.

Through their operations, they create combustible dust and so our team visited their site to be able to support the businesses safety by carrying out:

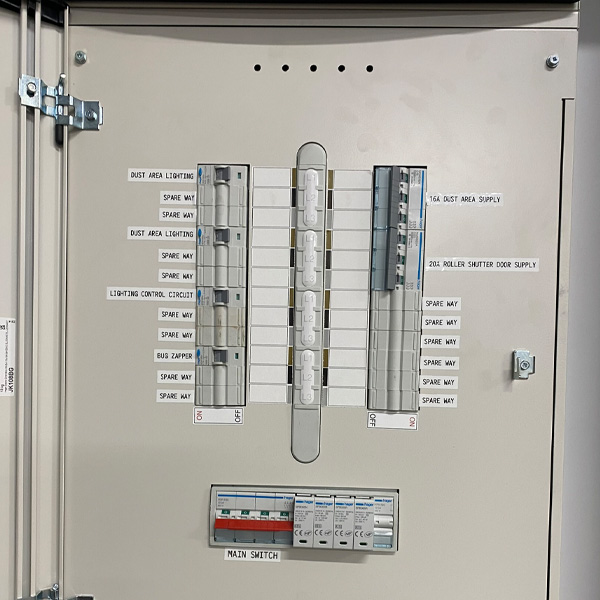

- The supply and installation of a new 630 amp rated 12-way panel MCCB board, complete with local CT metering and anti-surge protection device.

- Improvements to their sugar dryer control panels and dust extraction control systems through the supply and installation of 400 volt power supplies.

- A complete installation of ATEX certified low bay and emergency lighting, designed and fitted to their zone 22 area. This also included a local contactor control distribution board controlled by ATEX approved light switches.

As always with our installations, we ensure that everything is labelled correctly and fully accessible, leaving the customer with the assurance that their site is safe and orderly.

If you want to improve the safety of your site and make sure that your hazardous areas are fully secure, we would be happy to help!

We specialise in ATEX services, so whether it’s combustible dust or explosive atmospheres, our team are ready to assist nationwide. Enquire your interest, and get in touch with us today, here.

Latest News

View all

Your Quick Guide To Hazardous Area Lighting

Good lighting is crucial in keeping your facility well-lit and safe, however electrical ignition sources are one of the most common causes of fire and explosion in hazardous areas.

Read more about Your Quick Guide To Hazardous Area Lighting

Share

![]()

![]()

SR Electrical Will Be At CHEMUK 2024 This May!

We are excited to announce that SR Electrical will be at CHEMUK 2024 this Spring! The Chemical UK expo is the UK’s largest annual trade show for the chemical, laboratory and process industry.

Read more about SR Electrical Will Be At CHEMUK 2024 This May!

Share

![]()

![]()

Latest Projects

View all

ATEX Certified Hazardous Area Lighting and Emergency Lighting

Our team helped a business in the food industry improve the lighting in their hazardous areas with the supply and installation of fully compliant, ATEX certified fittings.

Read more about ATEX Certified Hazardous Area Lighting and Emergency Lighting

ATEX Lighting & Electrics Installation

Recently, we were called in to help a business in the food manufacturing sector with new hazardous area electrics at their site.