We know how serious and specialised electrical requirements are for businesses with hazardous areas. This is why our services are tailored to meet both your specific business needs and the industry regulations required to keep your site safe and compliant.

For over 20 years, SR Electrical Services has been providing:

Hazardous Area Electrical Inspections

Get your zoned areas inspected against regulations such as BS EN 60079-17, DSEAR, APEA and more. Our engineers conduct visual, close and detailed inspections with advanced equipment and finish the process by providing the relevant reports or certificates.

Hazardous Area Electrical Installations

From minor installations to total refurbishments, we’ve got your covered with our hazardous area electrical installations. We work across many sectors and have decades of experience delivering high quality results that last.

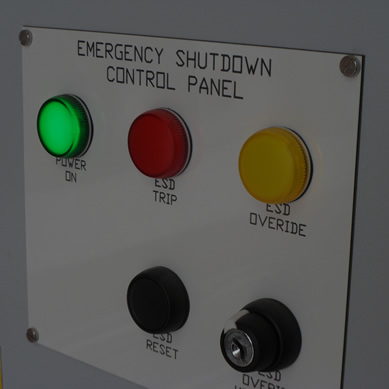

Electrical Control Panel Design & Build

Improve industrial automation and get higher-level monitoring with a bespoke control panel designed for your specific electrical system. Each control panel is fully tested at our workshop to guarantee it runs smoothly and efficiently once installed.

ATEX Inspections

If there is an explosive atmosphere present at your workplace, we can help reduce the associated risks and maintain a safe working environment through inspections by our CompEx accredited engineers.

Tank Gauging

Achieve new levels of monitoring and security with our range of Veeder Root TLS tank gauging systems, which utilise our patented FuelGuard remote cloud monitoring system. Our solutions give you complete control over your fuel stocks.

ATEX Design

Hazardous areas make designing projects more complex due to the presence of potentially explosive atmospheres. Luckily, our team of engineers have the skills and expertise to provide ATEX design services for businesses sector wide.

ATEX Lighting

We use our years of expertise and high-quality products to provide services that keep your site secure and well-lit.

DSEAR Assessments

If there is a potentially explosive atmosphere or the presence of dangerous substances at your business, then we can help ensure your workplace complies with The Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR).

Hazardous Area Classification Drawings

Hazardous

Area Classification drawings give you an overview of the presence of ignition

sources and potential risks to allow you to select and install equipment

without the worry of fire or explosion.

Recent Hazardous Area Projects

ATEX Certified Hazardous Area Lighting and Emergency Lighting

Read more about ATEX Certified Hazardous Area Lighting and Emergency Lighting

ATEX Lighting & Electrics Installation

Read more about ATEX Lighting & Electrics Installation

Header Point Lighting Rectification

Read more about Header Point Lighting Rectification

Latest News

View all

Your Quick Guide To Hazardous Area Lighting

Good lighting is crucial in keeping your facility well-lit and safe, however electrical ignition sources are one of the most common causes of fire and explosion in hazardous areas.

Read more about Your Quick Guide To Hazardous Area Lighting

Share

![]()

![]()

SR Electrical Will Be At CHEMUK 2024 This May!

We are excited to announce that SR Electrical will be at CHEMUK 2024 this Spring! The Chemical UK expo is the UK’s largest annual trade show for the chemical, laboratory and process industry.

Read more about SR Electrical Will Be At CHEMUK 2024 This May!

Share

![]()

![]()

Latest Projects

View all

ATEX Certified Hazardous Area Lighting and Emergency Lighting

Our team helped a business in the food industry improve the lighting in their hazardous areas with the supply and installation of fully compliant, ATEX certified fittings.

Read more about ATEX Certified Hazardous Area Lighting and Emergency Lighting

ATEX Lighting & Electrics Installation

Recently, we were called in to help a business in the food manufacturing sector with new hazardous area electrics at their site.