What is a safe area inspection?

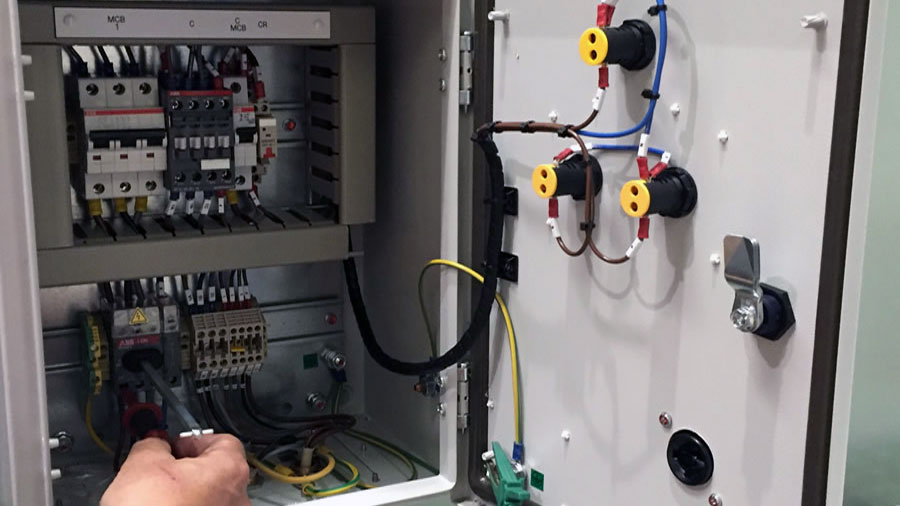

A safe area inspection is referred to an electrical installation condition report (EICR). The purpose of this electrical testing and inspection is to determine what if anything needs to be done to maintain the existing electrical installation in a safe and serviceable condition. The results of the inspection and testing are clearly detailed in the report noting any damage, deterioration, defects and dangerous conditions found in the existing installation that contravene the current addition and requirements of BS 7671.

We utilise licenced software to log test results onto a certificate when carrying out fixed wiring testing – this can be carried out by our engineers on their PDA’s to ensure that test results are captured efficiently and accurately at the time of test, the certificate is then uploaded to the office for finalisation by our qualified supervisors. Our software is updated automatically with any changes in legislation/guidance so that certificates issued are always the most up to date version possible.

- DB schedules are installed and if not, these are installed whilst on site.

- We will label all switches and sockets with circuit references.

- We provide a comprehensive list of defects on the certificate.

- As well as certificates issued, we can provide quotations for rectification of remedial defects.

- Install unique DB references, if required.

- Our engineers have PDA cameras so that any images of defective equipment or installation in areas can be recorded.

- Our engineers are also equipped with thermal imaging cameras to check distribution equipment to highlight any issues.

SELECT A CATEGORY

Latest News

View all

Your Quick Guide To Hazardous Area Lighting

Good lighting is crucial in keeping your facility well-lit and safe, however electrical ignition sources are one of the most common causes of fire and explosion in hazardous areas.

Read more about Your Quick Guide To Hazardous Area Lighting

Share

![]()

![]()

SR Electrical Will Be At CHEMUK 2024 This May!

We are excited to announce that SR Electrical will be at CHEMUK 2024 this Spring! The Chemical UK expo is the UK’s largest annual trade show for the chemical, laboratory and process industry.

Read more about SR Electrical Will Be At CHEMUK 2024 This May!

Share

![]()

![]()

Latest Projects

View all

ATEX Certified Hazardous Area Lighting and Emergency Lighting

Our team helped a business in the food industry improve the lighting in their hazardous areas with the supply and installation of fully compliant, ATEX certified fittings.

Read more about ATEX Certified Hazardous Area Lighting and Emergency Lighting

ATEX Lighting & Electrics Installation

Recently, we were called in to help a business in the food manufacturing sector with new hazardous area electrics at their site.

EICR

EICR

Emergency Lighting

Emergency Lighting

PAT Testing

PAT Testing

Thermographic Testing

Thermographic Testing