Our team installed Atex hazardous area lighting to help our client become, and remain, compliant.

Following a hazardous area specialist risk assessment of a site, carried out by a large, independent assessor to comply with DSEAR compliance - the SR Electrical team were asked to provide a quotation to carry out a hazardous area detailed inspection report. Upon completion of this report, we identified various electrical defects in the hazardous area, which required rectification. We were also able to identify some anomalies between the existing equipment and the updated hazardous area classification as stipulated in the risk assessment.

We provided a quotation detailing schedule of time and costs to complete the required remedial works, and also provided a regular inspection program over five years, to comply with current standards to allow the site to keep up-to-date with current regulations and maintenance requirements: BS EN 60079.

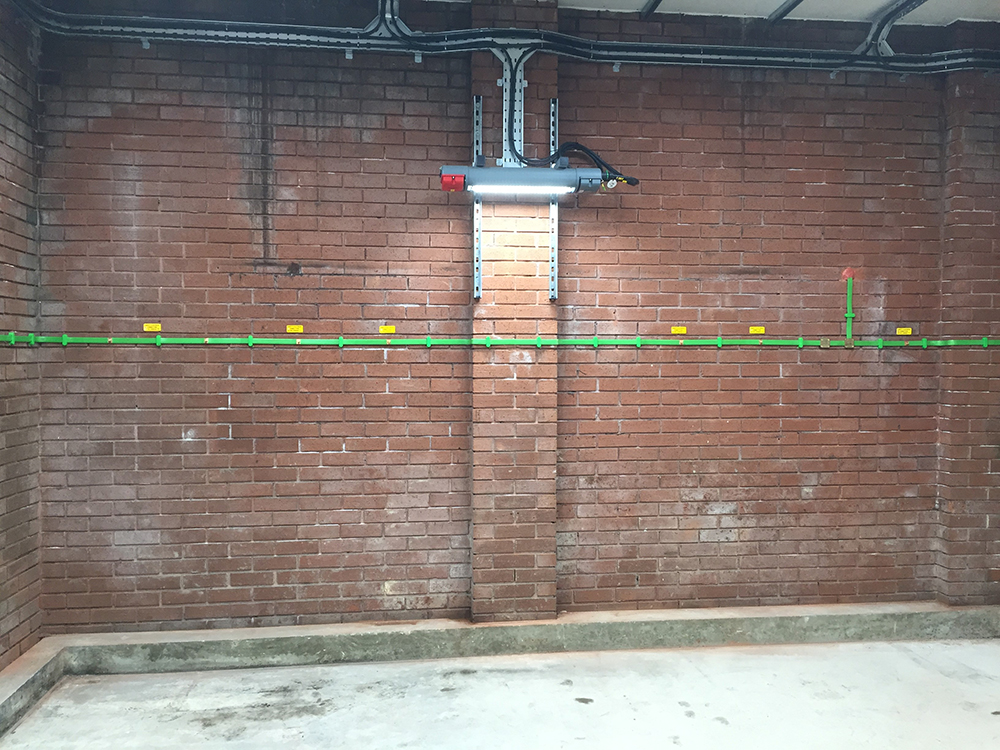

SR Electrical Services were given the task to provide a full electrical package - from design and installation, to commissioning and correctly approved/certified Atex Emergency Light Fittings to bring their current installation up to current regulations. As you can see from our project photos below, we had to install various medium duty cable trays and Unistrut support brackets in order to mount the Raytex Spartan LED light fittings and cabling containment.

The design was complaint to high task area readings, obtained due to the high-risk area assessment carried out to comply with current emergency lighting regulations BS 5266-1.

Latest News

View all

Your Quick Guide To Hazardous Area Lighting

Good lighting is crucial in keeping your facility well-lit and safe, however electrical ignition sources are one of the most common causes of fire and explosion in hazardous areas.

Read more about Your Quick Guide To Hazardous Area Lighting

Share

![]()

![]()

SR Electrical Will Be At CHEMUK 2024 This May!

We are excited to announce that SR Electrical will be at CHEMUK 2024 this Spring! The Chemical UK expo is the UK’s largest annual trade show for the chemical, laboratory and process industry.

Read more about SR Electrical Will Be At CHEMUK 2024 This May!

Share

![]()

![]()

Latest Projects

View all

ATEX Certified Hazardous Area Lighting and Emergency Lighting

Our team helped a business in the food industry improve the lighting in their hazardous areas with the supply and installation of fully compliant, ATEX certified fittings.

Read more about ATEX Certified Hazardous Area Lighting and Emergency Lighting

ATEX Lighting & Electrics Installation

Recently, we were called in to help a business in the food manufacturing sector with new hazardous area electrics at their site.